A New Perspective to Track Measurement

Track inspection technologies play a crucial role in preventing derailments and enabling data-driven maintenance planning. Based on previous FRA research, ~40% of track problems are found by track geometry and rail profile measurement systems alone. By FRA 213 and Transport Canada Track Safety Rules, track class or speed limits are determined by track geometry.

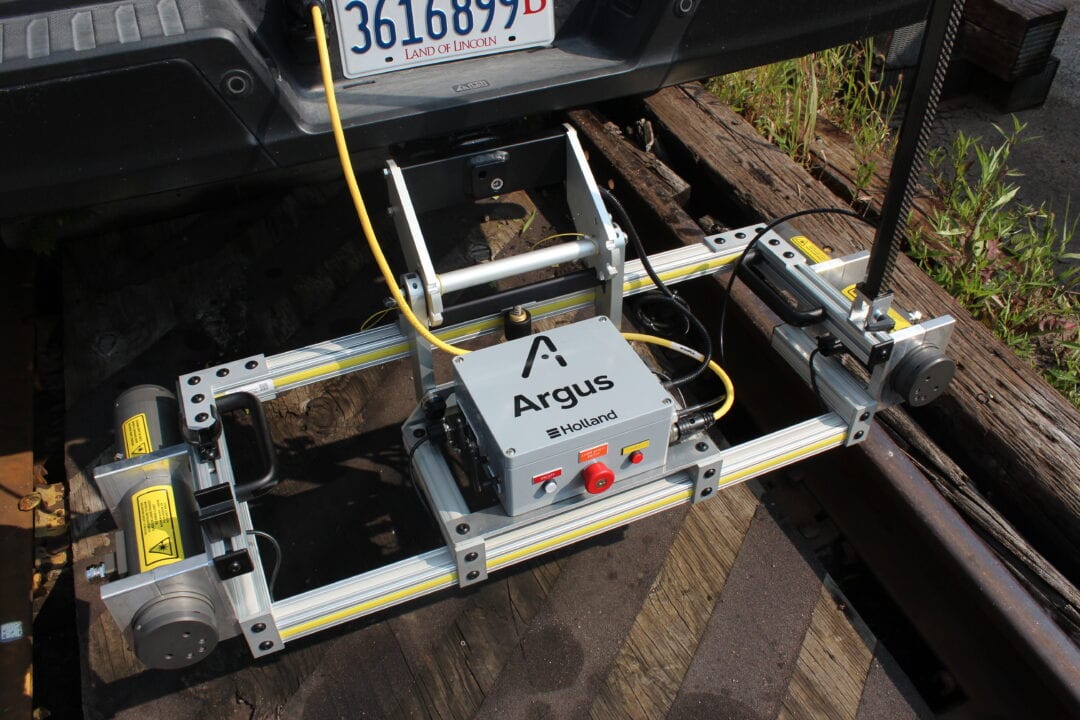

Measurements from Holland’s Argus track measurement technology provide the following values to railroads:

- FRA 213 and Transport Canada track geometry compliance

- Spot maintenance and operational safety

- Track maintenance and renewal planning

- Quality assurance or audit of track maintenance and repairs

- Critical input for railcar and vehicle track interaction modeling, derailment investigations

- Service and line changes and upgrades

Railroads determine the frequency and amount of track geometry and rail profile measurements based on the following factors:

- FRA 213 or Transport Canada track safety requirements

- Track class and type (mainline, siding, yard, industrial)

- Tie type (wood, concrete, steel, composite)

- Tonnage and traffic type (Freight, passenger, hazmat, long trains, axle load, uni-directional loaded vs empty trains)

- Climate characteristics (Extremely hot summers, extremely cold winters, excessive snow or rain, high daily day and night temperature difference)

- Terrain characteristics (frequent sharp curves, tunnels, bridges and culverts, steep grades)

Conventional track geometry and rail profile measurement systems are very costly due to requiring dedicated rail-bound or hi-rail vehicles, trained operators, and occupying revenue service tracks. In addition, sufficient measurements are not taken for trend or predictive analytics.

Holland brings a new perspective to track measurement with two innovative product lines to solve the core problems of conventional track geometry systems:

- Argus Portable Inspection Systems (Gauge and Track Inspector)

- Argus UGMS (Freight or Passenger Locomotive and Rail Cars)

Argus is a low-power, modular, compact, non-contact, inertial-based technology with measurement speeds up to 150 mph and operates in forward and backward directions. Argus systems generate the following track geometry measurements at every foot and rail profile measurements at every 10 feet:

- Track gauge and change rate (tight gauge, nominal gauge, wide gauge)

- Cross level/superelevation

- Surface and alignment (varying chord lengths up to 124 ft)

- Warp and twist (varying chord lengths)

- Runoff

- Degree of curvature

- Vmax and unbalance

- Additional custom geometry channels

- Half rail profile (rail head and gauge side of the rail)

- Full rail profile (rail head, gauge, and field side of the rail)

- Rail cant angle

- Rail weight/size

- Rail wear (vertical head, gauge face, total area loss)

- Gauge and field side lip

- Rail head slope, gauge face angle, base-to-height ratio

Argus measurements are located with a GPS and an encoder. Railroads provide track information such as timetable/speed limits, mile/kilometer post locations and equations, track centerline GPS coordinates (if available) and reference points. With customer-specific configurations, located standard and custom track geometry exceptions are provided real-time and near real-time from Argus Portable Inspection Systems and Argus UGMS, respectively. Rail profile is also collected along with track geometry. Rail size identification, vertical and gauge wear, rail head slope, gauge face angle, base-to-height ratio and lip area can also be provided by Holland’s Argus systems.