Global Welding Equipment

Holland is the premier provider of flash-butt welding rail welding equipment, service, parts, training, and application knowledge. Throughout our 85-plus-year history, Holland has been pioneering solutions to meet the needs of railroads across the world. Our success comes from our commitment to quality and innovation. Over the years, our systems have proven to be the most reliable and productive in the industry, performing over 30 million welds with our own equipment and employees, enabling Holland to set the standard for flash-butt welding on a worldwide basis.

Equipment Configurations

In addition to providing our customers with a variety of flash-butt rail welding machines, Holland LP offers several versatile equipment configurations to help deliver the welds to your track in the most efficient and productive manner.

H-650 (65 tonne) - High in-track production capacity

H-1000 (100 tonne) - Greater capacity for handling the longest rail strings

145 tonne Super Puller - Designed for closure welding and rail destressing in conjunction with our H-650 and H-1000 welding machines

G-head (80 & 130 tonne) - For welding specialty rails for overhead, gantry, and portal crane applications

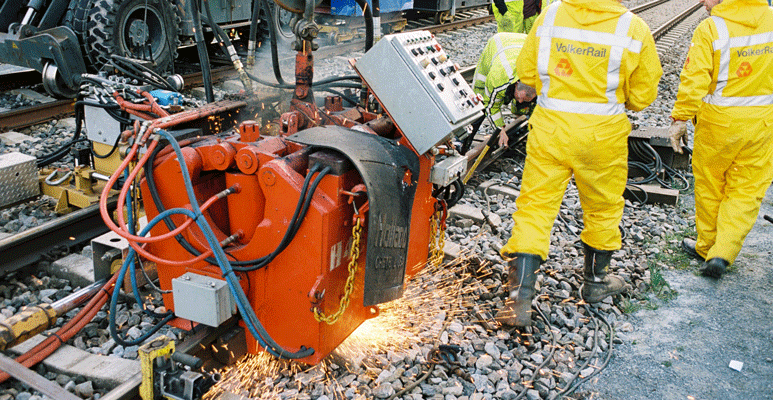

Skid Type Flash-Butt Welder

Our Skid Welder supplies the basic components to perform quality flash-butt welds and allows the customer to utilize their own equipment carrier, power unit and welding machine handling apparatus.

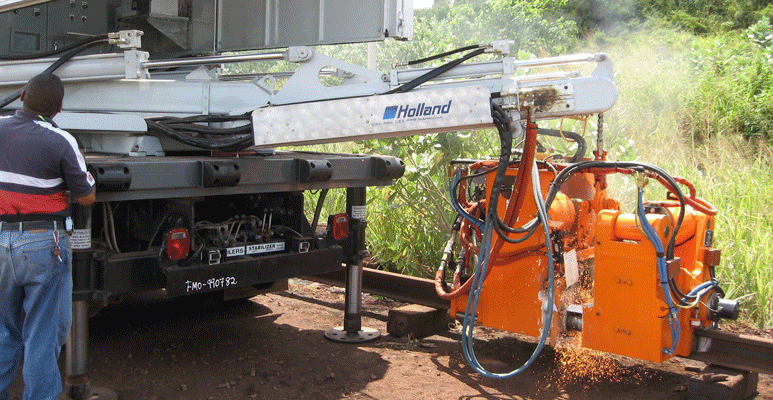

Container Welder Machine

Our Container Welder supplies the complete welding package, including a power unit and welding machine manipulator, in a compact and efficient configuration. It can be used as a stationary welding machine to generate long welded rail sections or on a customer-supplied mobile carrier to deliver in-track welds.

Flash-Butt MobileWelder®

Our MobileWelder® was first introduced to the industry and pioneered by Holland in 1979. This versatile flash-butt welding machine is a virtual mobile welding plant that can travel both on the rail and on the highway and is most easily relocated from one job site to another.

Training and Service

Our core values of family, respect, partnership, integrity, and improvement provide the foundation for everything we do. For our partners, this means we deliver our commitments to safety: striving towards zero injuries and accidents; quality: providing quality products and services and continually looking for ways to improve; and leadership: developing industry leading technology and employees.

Pre-Sale Assistance

Holland will explore your company’s specific needs including your unique application, environmental or certification requirements. Training and support needs are analyzed to ensure your solution is the right fit and within your budget.

Continued Post-Sale Support

Holland’s commitment doesn’t stop once the first weld is made. We continue to provide you with training, operator certifications, parts, and maintenance support. Replacement parts are inventoried and normally ready to ship within one business day.

Certifications

AREMA Chapter 4 – Rail 80-ES-035F-99-7001 / Brazil Section 02467 / Taiwan Rail Welding AS 1085.20 / Australian Standard / Welding of Steel Rail / Other country and local welding standards such as Malaysia, Singapore and Hong Kong TB 1632-85 / Department Standard of Rail Department of the Peoples Republic of China / Government of India Ministry of Railways - Manual for Flash Butt Welding of Rails / Network Rail / United Kingdom / Flash Welding Rails Standard EN 14587 - 2 / European Standard for Mobile Welding Machines Section B11 400 / Africa Field Welding of Rail Joints